Do you know about Repair Circuit Boards? Fixing a circuit board can seem daunting, but it becomes manageable with the right tools and knowledge. Whether you’re a hobbyist or a professional, understanding the basics of circuit board repair can save you time and money.

Circuit boards, or printed circuit boards (PCBs), are the backbone of most electronic devices. They hold electronic components together and provide the necessary wiring to function. Understanding their structure and function is the first step in mastering repairs.

Table of Contents

What is a Circuit Board?

A circuit board, also known as a Printed Circuit Board (PCB), is the backbone of most electronic devices. It holds and connects various components through conductive pathways, allowing the device to function correctly. Common issues with circuit boards include broken traces, faulty components, and poor solder connections.

Common Issues with Circuit Boards

Several problems can plague a Repair Circuit Boards: Ultimate Tips & Techniques Guide:

- Broken Traces: Pathways that have been physically damaged.

- Component Failure: Burnt out or malfunctioning parts.

- Cold Solder Joints: Poorly soldered connections that cause intermittent issues.

- Corrosion and Dirt: Build-up that can short circuits.

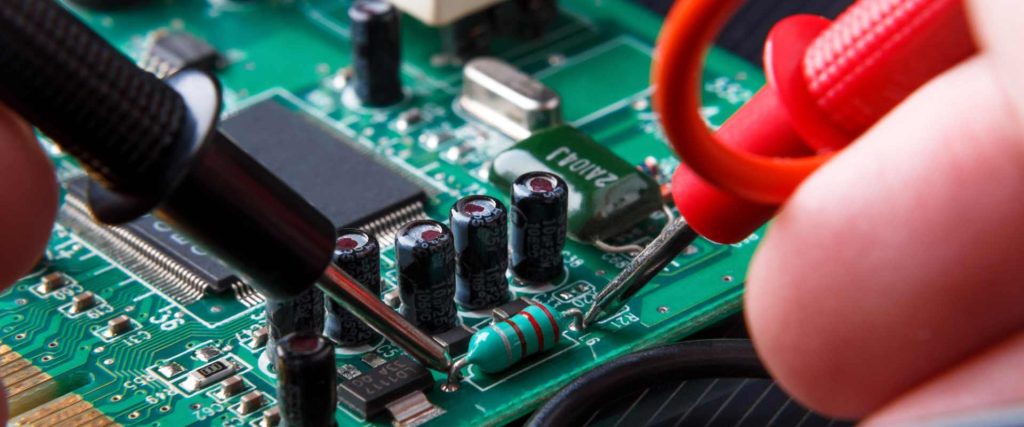

Tools You’ll Need for Repair

Before starting, gather these essential tools:

- Soldering Iron and Solder

- Desoldering Pump or Wick

- Multimeter

- Tweezers

- Magnifying Glass or Microscope

- Cleaning Solution and Brush

Preparing for Repair

Preparation is critical to successful repair:

- Safety First: Disconnect power and discharge capacitors.

- Workspace: Set up a clean, well-lit area.

- Documentation: Have schematics or diagrams of the board.

Step-by-Step Guide to Repair Circuit Boards: Ultimate Tips & Techniques Guide

- Identify the Issue: Use a multimeter to test continuity and locate faults.

- Remove Damaged Components: Desolder and safely remove faulty parts.

- Clean the Board: Use a cleaning solution to remove corrosion and debris.

- Repair Broken Traces: Use a conductive pen or wire to fix broken pathways.

- Replace Components: Solder new or replacement parts onto the board.

- Test the Repair: Check for continuity and proper function before reassembly.

Tips for Successful Circuit Board Repair

- Patience and Precision: Take your time to avoid mistakes.

- Use Quality Tools: Good tools make a significant difference.

- Double-Check Work: Always verify repairs before powering up.

Advanced Repair Techniques

For more complex issues:

- BGA Rework: Requires special equipment for reworking ball grid array components.

- Micro Soldering: For very fine or surface-mount components.

- Reflow Soldering: Using heat to resolder connections en masse.

Preventive Measures to Avoid Damage

Keep your circuit boards in top shape with these tips:

- Avoid Static: Use anti-static mats and wristbands.

- Proper Handling: Hold boards by edges and avoid flexing.

- Regular Cleaning: Keep boards free from dust and debris.

Why Do Circuit Boards Fail?

Circuit boards can fail for several reasons:

- Physical Damage: Dropping or mishandling the device can break the board or its components.

- Overheating: Excessive heat can damage components or the board itself.

- Electrical Overload: Power surges can fry components.

- Corrosion: Exposure to moisture or chemicals can corrode the board.

Frequently Asked Questions about Repair Circuit Boards

Can all circuit boards be repaired?

Most can, but severe damage or proprietary designs may limit your ability to repair.

What should I do if I can’t find the issue?

Revisit the problem with fresh eyes or consult a professional for complex problems.

How can I improve my soldering skills?

Practice regularly and consider taking a course or watching tutorials online.

Final Words

Repair Circuit Boards: Ultimate Tips & Techniques Guide is a valuable skill that can prevent costly replacements. By understanding the common issues, having the right tools, and following a systematic approach, you can fix most problems effectively. Happy repairing!